1. The Importance of Correct Pallet Box Selection

Choosing the right plastic pallet box is more than a simple procurement task; it’s a strategic decision that directly impacts your operational efficiency, product safety, and bottom line. Selecting an incorrectly sized or under-specified box can lead to product damage, inefficient space utilization, workplace accidents, and costly compliance failures. This guide breaks down the plastic pallet box selection process into five critical parameters, empowering you to make an informed decision that enhances your logistics and storage workflows.

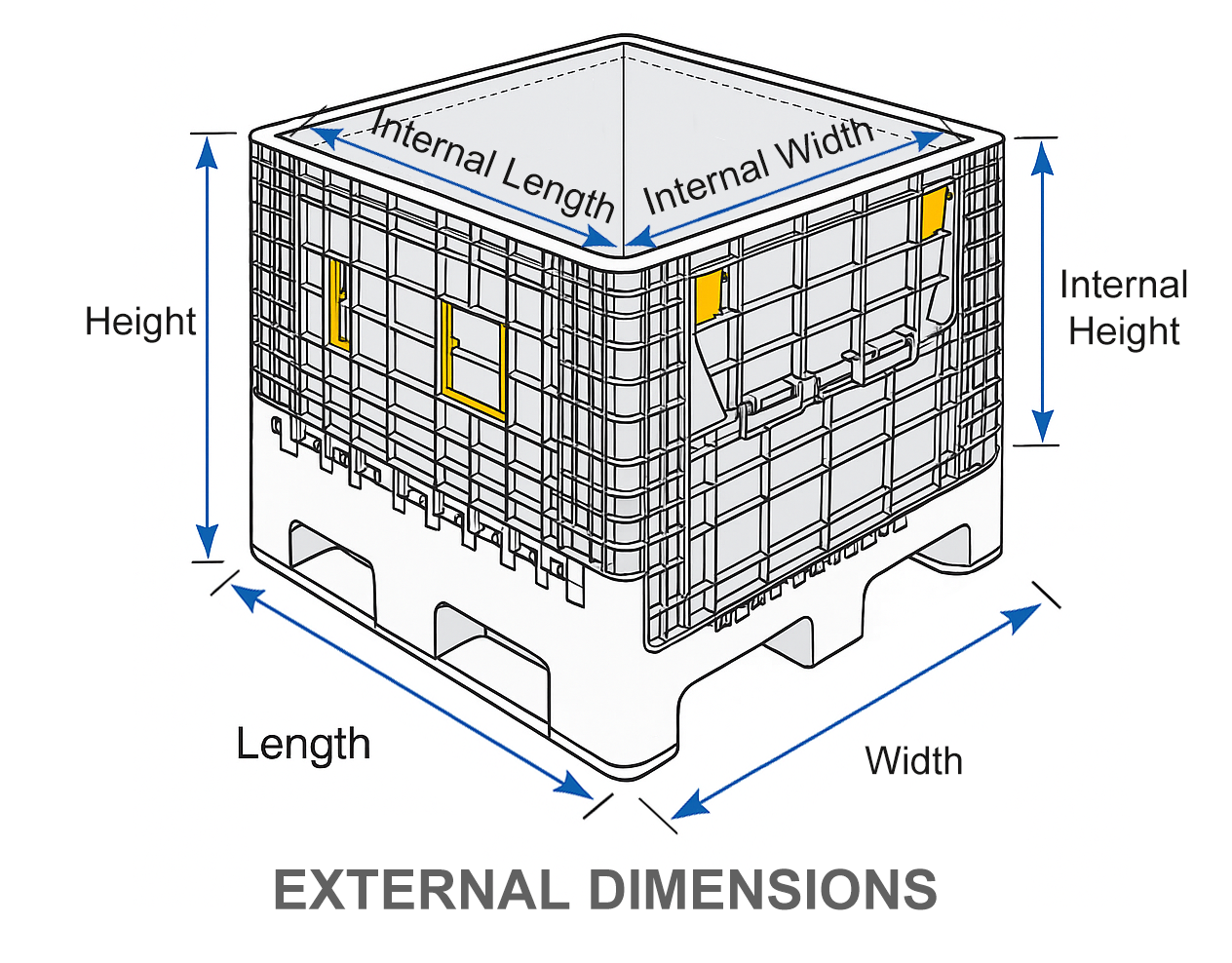

2. Pallet Box Dimensions

The first step in selecting a pallet box is ensuring it physically fits both your products and your infrastructure. Misjudging dimensions can lead to wasted space or an inability to handle the boxes with your existing equipment.

External vs. Internal Dimensions: What You Need to Know

It’s crucial to differentiate between two sets of measurements:

- External Dimensions (L x W x H): These determine how the box fits in your warehouse racking, on transport vehicles, and through doorways. Plan your storage density and transit loads based on this.

- Internal Dimensions (L x W x H): This is the usable space for your products. Always use these figures to calculate if your goods will fit inside.

3. Understanding Pallet Box Capacity and Safety Margins

The load capacity dictates how much weight a box can safely handle. Exceeding the specified pallet box capacity is a major safety hazard and can lead to catastrophic failure.

Static, Dynamic, and Racking Loads Explained

You will typically see three load ratings:

- Static Load: The maximum weight the box can hold when stationary on a flat surface (e.g., stacked in a corner). This is always the highest value.

- Dynamic Load: The maximum weight the box can hold while being moved by equipment like a forklift or pallet jack.

- Racking Load: The maximum weight the box can hold when placed on a pallet rack with support only on the front and back beams. This is usually the lowest value.

| Load Type | Description | Key Consideration |

|---|---|---|

| Static | Box is at rest on a solid floor. | For block stacking and storage density. |

| Dynamic | Box is being lifted and moved. | For operational safety during transport. |

| Racking | Box is stored on a pallet rack. | For high-density warehouse storage systems. |

Applying a Safety Margin

For operational safety, never load a box to 100% of its dynamic or racking capacity. A standard industry practice is to maintain a 15-20% safety margin.

Calculation: Maximum Operational Load = Rated Capacity x 0.80

This buffer accounts for uneven loading, minor impacts during handling, and environmental factors, ensuring longevity and a safer workplace.

4. Stackability and Its Impact on Warehouse Automation

Stackability refers to a pallet box’s ability to be stacked securely on top of another, both when empty and full. This feature is fundamental for optimizing warehouse footprint and is critical for automated systems.

Poorly designed stacking features can lead to unstable loads, posing a risk to personnel and products. When evaluating stackability, consider:

- Load Distribution: Does the design evenly distribute the weight of the stack?

- Compatibility with Automation: Are the dimensions and base design compatible with your conveyors, shuttles, or Automated Storage and Retrieval Systems (AS/RS)? The clearance and stability must meet the precise tolerances of automated equipment.

5. Material, Hygiene, and Key Certifications

The material of the pallet box determines its durability, temperature resistance, and suitability for specific industries, especially food and pharmaceuticals.

Common Materials (HDPE vs. PP)

- HDPE (High-Density Polyethylene): Excellent for cold environments and freezer use. Highly resistant to impact and chemicals. This is the most common choice for food processing.

- PP (Polypropylene): Stiffer and more suitable for warmer environments. It performs well in applications requiring high rigidity and stacking strength at room temperature.

Understanding Food-Grade and Other Certifications

For supply chains involving food, pharmaceuticals, or other sensitive goods, certification is non-negotiable.

- Food-Grade Certification: This confirms the plastic is made from virgin, non-toxic materials (like HDPE) and is safe for direct contact with food.

- EU 10/2011 & FDA Compliance: These are key regulations for plastic materials intended to come into contact with food. The EU standard is widely recognized globally.

- HACCP Principles: While not a certification for the box itself, a box designed with smooth surfaces and rounded corners supports HACCP (Hazard Analysis and Critical Control Points) principles by being easy to clean and preventing bacterial growth.

6. Finalizing Your Selection: A Quick Checklist

Making the final decision is about matching the parameters above to your unique operational needs. Use this checklist as a final review:

- Dimensions: Do the internal dimensions fit my product, and do the external dimensions fit my infrastructure?

- Capacity: Is the dynamic and racking load sufficient for my heaviest products, including a safety margin?

- Stackability: Is the design stable and compatible with my manual and/or automated handling equipment?

- Material: Is the material (e.g., HDPE) suitable for my temperature and operating environment?

- Certification: Does it have the required food-grade certification or other compliance documents?

Ready to find the perfect pallet box for your operations? Take the next step with our expert resources.

- Get a precise match for your needs. Learn about our pallet box products.

- Have a unique requirement or need expert advice? Request a Quote or Consult with Our Team Today!