Learn how to select the right plastic pallet box for beam racking, shuttle systems, and AS/RS. This guide covers racking loads, dimensions, base structures, materials, safety, and ROI.

Overview

A plastic pallet box integrates a heavy-duty pallet base with a large-volume container for stacking, forklift handling, and closed-loop circulation. It is widely used in food and beverage, cold chain, fresh produce, automotive parts, e-commerce, pharmaceutical, and chemical warehouses. Compared with a tote-plus-pallet combination, a one-piece pallet box offers better stability on beams, higher cube utilization, and safer racking.

Why use plastic pallet boxes on racking

- Structural strength and stability: One-piece base and walls distribute load evenly and resist deflection on beams.

- Handling efficiency: 4-way entry supports forklifts, reach trucks, and AGV/AMR.

- Hygiene and durability: HDPE/PP resists corrosion, is easy to clean, and works in cold rooms.

- Safety: Optional steel reinforcements, anti-slip pads, and edge guards reduce fall risk.

- Cost efficiency: Collapsible versions cut return freight and support long service life.

- Traceability: Supports RFID, QR plates, and laser codes for WMS/AS/RS integration.

Key racking-fit parameters (what to check)

Size standards

- Euro: 1200 × 800 mm

- International: 1200 × 1000 mm, 1100 × 1100 mm, 1140 × 1140 mm, 48 × 40 in

- Height: typically 760–1000 mm (box + base); verify beam clearances and lift heights

Load ratings (UDL—uniformly distributed load)

- Static (floor stacking): 1000–5000 kg

- Dynamic (handling/conveying): 500–1500 kg

- Racking load: 300–1000 kg depending on steel reinforcement and beam span

Note: Always validate racking load by span and temperature, and ensure deflection within limits—often ≤ L/200. Never substitute static load for racking use.

Materials and manufacturing

- HDPE: superior low-temperature toughness and impact; common for food-grade and cold chain.

- PP: higher stiffness and heat resistance.

- Processes: injection-molded (precision/strength) or blow-molded (lighter, impact-resistant).

- Food contact: FDA/LFGB materials available.

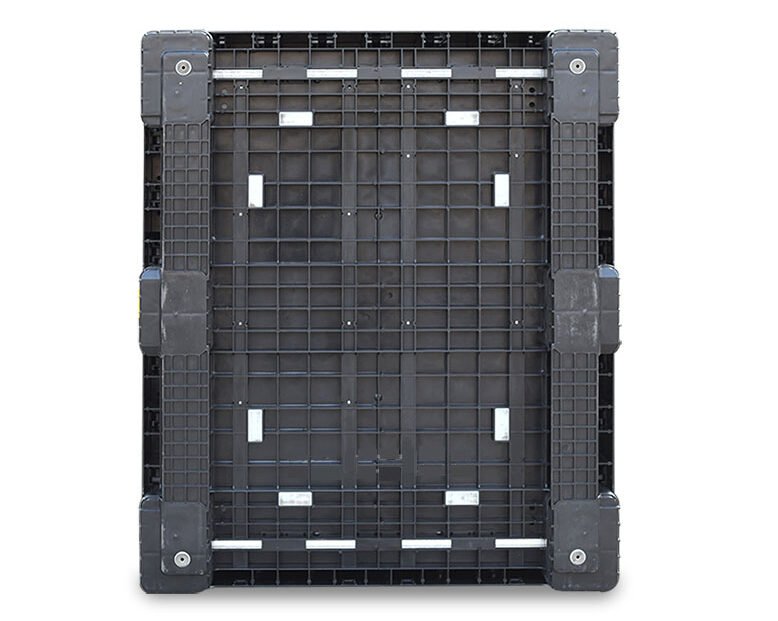

Bottom structure

- 3 runners (3 skids): preferred for racking stability across beams.

- 9-foot/6-foot: floor use; not recommended directly on beams.

- Steel reinforcements: fitted in runners or perimeter to increase racking load and reduce deflection.

Box types and features

- Solid walls: maximum strength, leak-proof.

- Vented walls: airflow for produce and fast cooling.

- Collapsible: 50–70% return volume reduction.

- Drop door: ergonomic picking on rack.

- Lids: dust protection and safer stacking.

Compatibility and safety

- Racking: Selective, Drive-in, VNA, Shuttle, and AS/RS.

- Beam span: commonly 800–1200 mm; consult vendor racking load curves.

- Temperature: typical -30°C to +60°C; validate for extreme cold storage.

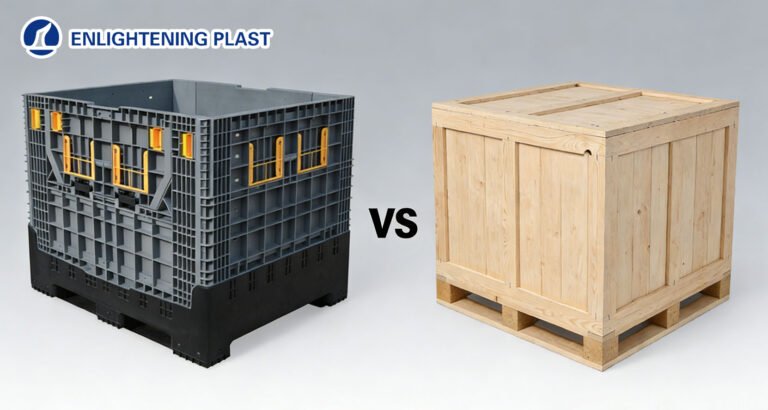

Plastic pallet box vs wood/metal

- Versus wood: hygienic, splinter-free, dimensionally stable, moisture-resistant.

- Versus metal: lighter, less wear on beams, better total cost of ownership; metal excels only in extreme, heavy-duty cases.

Best practices for safe, efficient racking

- Uniform loading; avoid point loads and off-center weight. Keep the center of gravity within ±50 mm of center.

- Use 3-runner bases with steel tubes for racking; verify beam span against manufacturer data.

- Fork handling: 4-way entry at < 5 km/h; fork length and spacing must support runner load zones.

- Deflection control: confirm combined weight and temperature meet deflection limits.

- Stacking: obey static test limits (typically 2–4 layers on floor); do not add loads on racked units.

Typical specification examples

- 1200 × 1000 × 760 mm, 3 runners, HDPE, static 3000 kg, dynamic 1000 kg, racking 600 kg, 3 steel tubes, solid walls with lid.

- 1200 × 1000 × 975 mm, collapsible, PP/HDPE blend, static 2000 kg, dynamic 800 kg, racking 400 kg, front drop door.

- 1200 × 1000 × 1000 mm, HDPE, cold-store grade, usable at -30°C, anti-slip rim and guided fork pockets.

Always confirm final ratings with supplier test data and your racking beam span.

Selection workflow

- Identify rack type and beam span.

- Define max net load per box and temperature range.

- Select a 3-runner base; add steel tubes for racking.

- Choose standard footprint (EU/US/AP) to fit aisles, conveyors, and shuttles.

- Pick box style (solid/vented/collapsible/drop door/lid).

- Validate racking load curve and deflection; run a 24–48 h trial on-site.

- Check compliance needs (food contact, ESD, UN dangerous goods if applicable).

Use cases

- Food and beverage: raw materials, packaged goods, cold storage, racked picking.

- Fresh produce: vented walls with cold chain; shuttle or AS/RS.

- Automotive parts: collapsible with custom dunnage; VNA high-bay warehouses.

- Pharma and personal care: solid with lids in clean areas.

- E-commerce and 3PL: standardized footprints with RFID for high throughput.

- Chemicals and powders: solid leak-proof walls; consider UN certification.

Costs and ROI

- Upfront cost is higher than wood, but 5–10 years lifespan lowers per-trip cost.

- Collapsible versions reduce backhaul volume by 20–40%.

- Lower damage and rack wear; throughput improvements of 5–15% are common.

FAQ

Can a plastic pallet box sit directly on beams?

Yes—use a 3-runner base and preferably steel reinforcement, and follow the manufacturer’s racking load data. 9-foot bases are not recommended for beams.

What’s the difference between racking, dynamic, and static load?

Racking load is usually the lowest due to span/deflection limits. Do not substitute static load for racking applications.

Is it suitable for cold rooms?

Yes—use low-temperature grade HDPE with anti-slip features. Validate in -30°C environments with on-site trials.

Do collapsible boxes have lower ratings?

Often yes compared to solid walls. Verify specs or select reinforced models if racking loads are critical.

How to match AS/RS or shuttle systems?

Confirm runner spacing and guide features match equipment tines; verify stiffness and repeatable positioning.