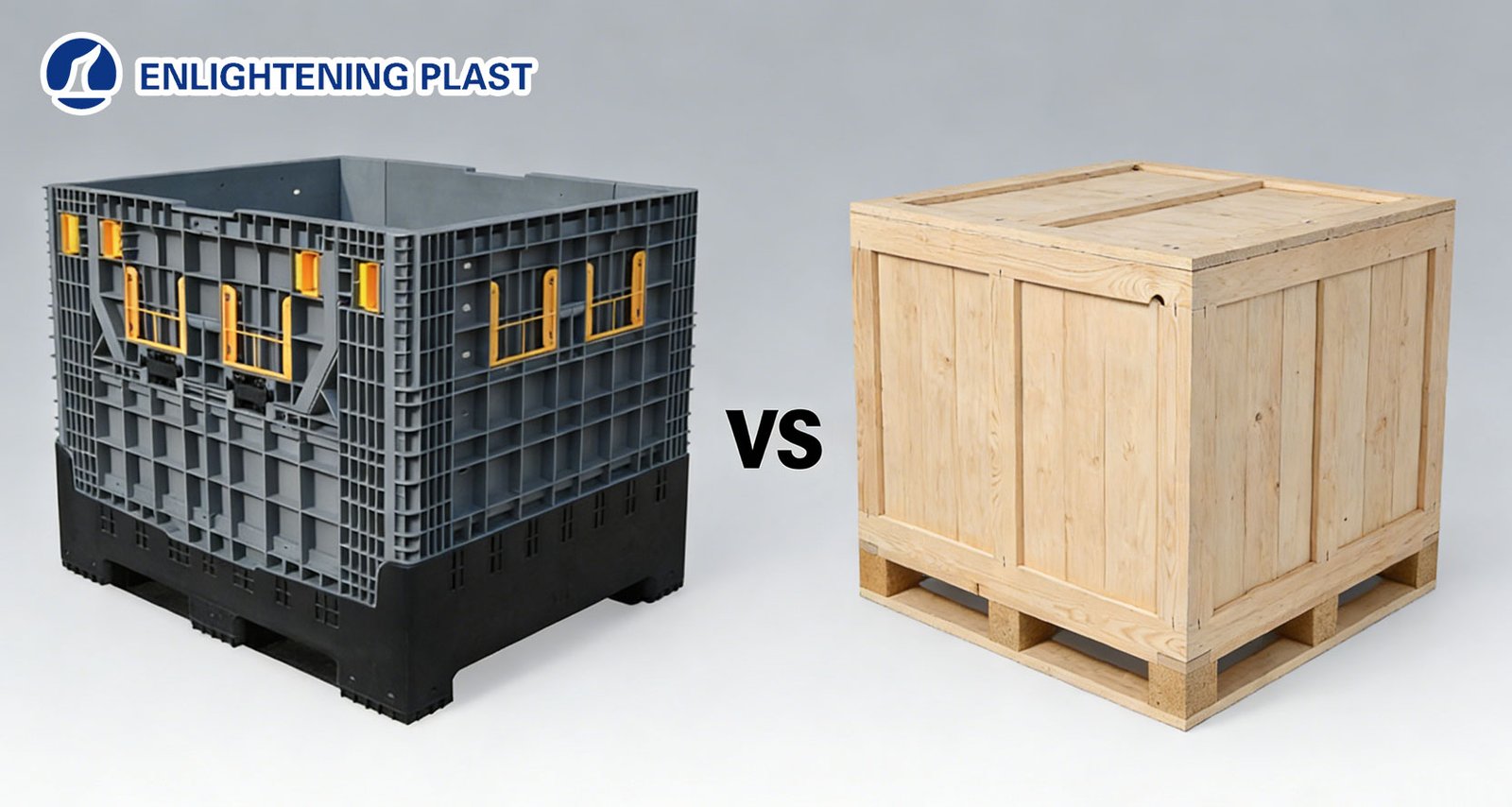

In warehousing and logistics, choosing between plastic pallet boxes and wooden pallet boxes requires balancing durability, hygiene standards, automation compatibility, and total cost. Below is a structured comparison and selection guide.

Definitions and typical applications

Plastic pallet box

- Material: HDPE or PP, high-strength closed/semi-closed structure

- Features: High standardization of dimensions, corrosion and water resistance, easy to clean

- Applications: Agriculture, e-commerce logistics, auto parts, electronics, food, pharmaceuticals, waste recycling; suitable for high-frequency circulation

Wooden pallet box

- Material: Wood-based, diverse structures

- Features: Strong load-bearing, low initial cost,Flexible processing/customization

- Applications: Manufacturing, construction materials, bulk goods; humidity- and impact-sensitive items need extra protection

Materials and durability comparison

Durability and hygiene of plastic pallet boxes

- Resistant to corrosion, chemicals, mold, and water; usable from -40°C to +70°C

- Smooth surfaces suitable for high-pressure washing and disinfection; optional food-grade certification

Durability and hygiene of wooden pallet boxes

- Susceptible to humidity, mold, and pests; may deform, crack, and gain weight

- Porous surfaces are hard to clean; prone to dust and microbes; not ideal for high-standard cleaning

Recycling and circular use

Plastic pallet boxes

- Reusable and recyclable with long lifecycle; unit cost drops as turnover increases

- Mature recycling systems; aligns with green supply chain and circular economy

Wooden pallet boxes

- Reusable but shorter lifespan; higher dismantling and reprocessing costs

- Recycling systems are less developed in some regions; exports must comply with ISPM-15

Cost structure and ROI

Initial cost

- Plastic: Higher per-unit cost, but better annualized cost in high-frequency and high-compliance use

- Wood: Lower initial outlay; suitable for one-off or low-frequency shipments

Maintenance and turnover cost

- Plastic: Durable, easy to clean, low breakage and write-off rates; lower compliance costs for cold chain and food/pharma

- Wood: Requires moisture and pest treatment; higher breakage and loss rates increase turnover costs

Transport and storage performance

Weight and handling

- Plastic: Lighter weight improves loading/unloading efficiency; friendly to automated warehousing

- Wood: Heavier and harder to handle; higher labor cost; less compatible with automation

-

Automated warehouse with AGVs handling plastic pallet boxes

Dimensions and standardization

- Plastic: Highly standardized; integrates well with pallets, racking, conveyors, AGVs, and RFID/barcodes

- Wood: Flexible customization but lower standardization; higher cross-system matching cost

Stacking and space utilization

- Plastic: Good stacking and self-closing designs increase storage density

- Wood: Stackable but typically lower density than plastic boxes

Hygiene, safety, and compliance

High-compliance industries (food/pharma/electronics)

- Plastic: Easier to meet hygiene and safety standards (food-grade materials, HACCP/ISO 22000, optional IP ratings)

- Wood: Often needs extra coverings or sealing; higher compliance cost

Logistics safety and damage risk

- Plastic: Moisture/mold/pest resistant; reduces cargo damage and cross-contamination

- Wood: Higher risk in humid environments; needs additional protection

Global market trends

Sustainability and circular economy

- Green supply chains favor recyclable and recycled materials; plastic boxes support ESG goals

Automation and digitalization

- Automated warehousing, smart sorting, and RFID/barcodes increase demand for standardized, durable, easy-to-clean containers

- Plastic boxes cooperate better with automation equipment

Cold chain and high-end applications

- Food and pharma require strict temperature and hygiene; plastic pallet boxes are more competitive

Cost sensitivity and customization

- Wooden boxes still fit budget-sensitive, one-off, or low-frequency scenarios

- Long-term total cost and efficiency considerations favor plastic boxes

Selection criteria: When to choose plastic pallet boxes?

- High strength, long-term circulation, frequent inbound/outbound

- Strict hygiene and cleaning needs in cold chain, food, pharma, electronics, FMCG

- High compatibility with automation, pallet management, and palletizing systems

- Lower maintenance cost and higher recyclability

- Clear ESG and green packaging objectives

Selection criteria: When to choose wooden pallet boxes?

- Initial cost sensitivity, short-term circulation, one-off or low-frequency operations

- High load and impact resistance needs with controlled environments

- High customization on shape and openings

- Established wood box recovery systems and acceptable total cost

Practical advice and implementation

Conduct lifecycle cost analysis (LCC)

- Include procurement, transport, maintenance/cleaning, write-off rates, and residual value to compute true unit cost and payback

Focus on compliance and standardization

- Prioritize food/pharma-grade plastic materials; ensure compatibility with racks, pallets, conveyors, and WMS

Zone-based mixed use

- Use plastic for high-frequency, high-hygiene stages; wood for low-frequency or high customization to balance cost and efficiency

Sustainability and brand

- Adopt recycled-material plastic boxes and mature recovery systems; strengthen green certifications and supplier evaluations

FAQ

What are the core advantages of plastic vs. wooden pallet boxes?

Higher durability, easier cleaning, better fit for automation and cold chain, longer lifecycle, mature recycling, and lower long-term annualized cost.

When are wooden pallet boxes more cost-effective?

For one-off or low-frequency shipments, limited budgets, high load/custom needs, and controlled environments.

Which is better for food and pharma?

Plastic pallet boxes with food-grade materials and easy disinfection (HACCP/ISO 22000). Wooden boxes require extra sealing and compliance steps.

What should I consider when exporting with wooden boxes?

Comply with ISPM-15 (fumigation or heat treatment) to meet phytosanitary standards and avoid clearance delays.

Are plastic pallet boxes suitable for RFID or barcode tracking?

Yes. Their surfaces facilitate label adhesion or embedded RFID, improving warehouse and logistics visibility.

Conclusion and CTA

If your goal is cost reduction, compliance, automation synergy, and lower cargo damage, plastic pallet boxes offer better value in most global scenarios.

You can contact Enlightening Plast for sample testing and LCC (Life Cycle Cost) evaluation, and conduct pilot tests in conjunction with your warehousing system and cold chain requirements before full-scale deployment.

For customized quotes or sample testing, please contact our sales team.